Cold Spray

Application of New Metal Deposition Technology for In-field Restoration of Bronze, Zinc, Lead and Cast Iron Art Works Technology

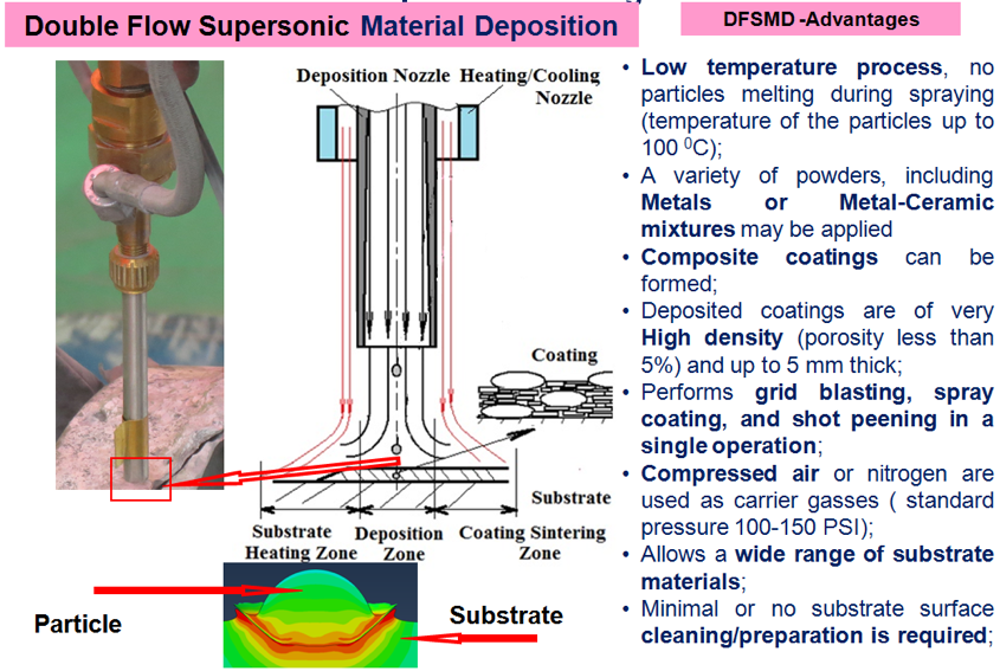

True Image Solution (TIS) Co, UK, TESSONICS Inc. and Institute for Diagnostic Imaging Research (IDIR), Canada constantly review the development of new non-invasive art work analysis methods and subsequent restoration by advanced deposition and patination methods. The new Double Flow Supersonic Material Deposition (DFSMD) method developed by TESSONICS and IDIR ensures precise local restoration of damaged areas at near ambient temperature due to dual flow of propellant and cooling gas. The principle and advantages of DFSMD are shown on Fig.1

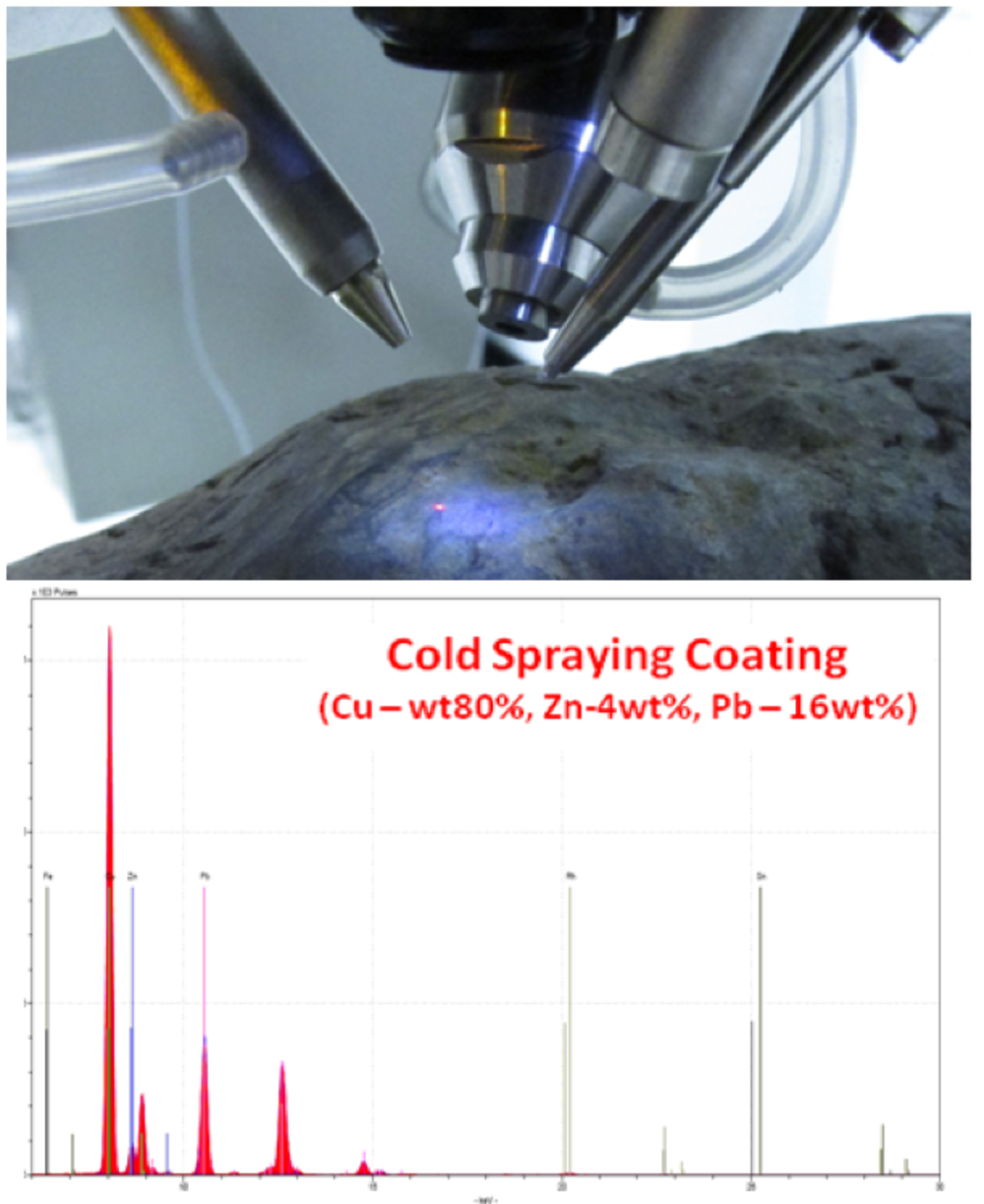

A critical strategy in defining this restoration technology is the application of non-invasive analysis and DFSMD technology. The first step analyses the exact chemical composition of the subject material (Figure 2). Based on these results a powder is formulated for deposition by DFSMD and the optimum operating parameters for powder deposition are also defined. The cooling air fed through the cooling nozzle (Fig.1) effectively cools the surface of the artwork undergoing restoration, this process prevents significant heating of the material and diminishes any impact on the restoration subject.

Art-Works Restoration Technologies and DFSMD Application

Cast metals have been employed in sculpture for centuries, offering durability, strength and the ability to retain fine detail. However, all cast sculptural metals are brittle and so vulnerable to frost and impact and environmental damage often requiring restoration.

Bronze, zinc and lead have been in use from antiquity, due largely from their ability to be cast at low temperatures. All are durable metals with attractive natural surfaces which weather well – although the appearance of bronze was often enhanced by artificial treatment or patination. Lead and zinc being soft and heavy, usually requires an internal metal support-structure, which may itself be susceptible to corrosion or degradation.

If Iron was used for the substructure then rust can form in the presence of moisture and airde and, as it does so, the rust expands to up to ten times the volume of the original iron. So lead sculpture is particularly vulnerable to splitting and collapse as the sub-structure is weakened. Lead itself is generally resistant to corrosion and, if unpainted, the surface will develop a protective natural patina. As a soft material, impact damage is commonly found on lead sculpture in the form of superficial dents and scratches to the surface and as such it is particularly vulnerable to vandalism.

Usually the conservation of lead and zinc sculptures often necessitates removal of the original substructure and core material followed by the insertion of a new stainless steel substructure. This may require cutting patches and sections to allow access. Use of DFSMD restoration technology allows the original substructure and core material to remain in place with protection of original materials by DFSMD anti-corrosion coatings. To achieve the bronze effect the zinc sculptures were frequently electroplated in copper. At present time, outdoor zinc sculptures have usually lost their original surface coatings and copper plating through environmental degradation, exposing the grey coloured zinc. The corrosion may cause the zinc to have a very pitted surface, accompanied by failure of the lead solder joints which can compromises further the object's structural integrity and leaveing it vulnerable to serious fractures and increased corrosion. The DFSMD copper coating avoids electroplating and achieves effective restoration of pitted surfaces.

Cast iron is also strong and durable, but difficult to join. As a result it is vulnerable to water penetration and requires frequent painting. Additionally a lot of cast iron structures have missing detail because of its brittleness. Application of DFSMD technology can demonstrate a good build-up of deposited material which offers the opportunity to restore that missing detail in the field. This DFSMD capability allows the production of 3D shapes and art-works as shown on the Figures 3,4

TIS-TESSONCS-IDIR Consortium provides the following restoration services:

- General cleaning

- Corrosion damage restoration

- Crack, wear and fracture restoration

- Restoration of missing elements

- In-field coating

- Substructure damage repair

- Patination processes

TIS and TESSONICS employs a team of material science and technology experts and professionally trained restorers who have worked in museums across Canada and Europe. Our professional experience includes the Getty Conservation Institute (Los Angeles, USA), Detroit Institute of Arts (Detroit, USA), Rijksmuseum (Amsterdam, the Netherlands), Pushkin Museum of Fine Arts (Moscow, Russia), Hermitage State Museum (St. Petersburg, Russia) and others. Among the projects IDIR is actively working on today is a research collaboration with Hamilton-Kerr Institute (Cambridge, UK) related to the analysis of the structure and conservation state of a set of ancient paintings from Fitzwilliam Museum (Cambridge, UK) and Louvre Museum (Paris, France).